What Does Custom Jewelry Cost?

October 10th, 2012 by James L. Sweaney, CGA, FGA. GGJewelry making is an ancient craft dating to the dawn of civilization. Prior to the mid 1800’s and the Industrial Revolution, fine jewelry of precious metals and gems was made mainly for royalty and the very rich. Today, through advances in technology, almost anyone looking for a quality piece of jewelry can afford one-of-a-kind custom jewelry.

Virtually all custom jewelry is made in three main steps– first the concept and design, then construction of the piece either by casting or fabrication, then adding the final touches of polishing, stone setting, and finishing.

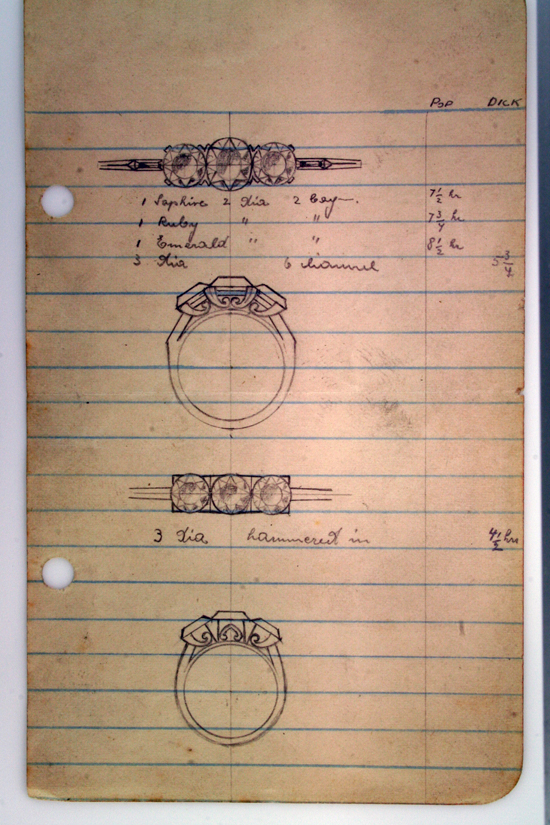

In the past, the jeweler typically developed the design with concept sketches, work drawings, then laboriously drew or hand painted elaborate renderings (above) to show clients for design approval.

Once the design was approved, the jeweler constructed the piece in one of two main ways. He would hand carve the model in wax, then cast it into precious metal, ready for finishing, or fabricate it in metal, working directly with metal wires and sheet, cutting, sawing, shaping, fitting and soldering components together into the jewelry item.

While there have been many innovations in jewelry setting and finishing techniques, these new methods are suited more for mass produced pieces. Then and today, most one-of-a-kind pieces are polished, set and finished with hand-craft methods handed down thru the generations.

Now, through the wizardry of computer aided design (CAD), the team at Mardon creates the custom design in 3D programs specialized for making jewelry. This design can be shown from different angles and magnifications, allowing straightforward visualization for both jeweler and client. Design modifications are easily done before the piece is made. The real beauty of CAD is that the design is actually a virtual model that can be machined or grown into a physical model thru computer aided modeling (CAM).

Since CAD/CAM combines design and construction into one precise and efficient process, your cost for an original one-of-a-kind piece of jewelry is much more reasonable than you might expect. The fees for the original design, castable model, casting and finishing of our custom pieces are generally about $400 – 500. To this, the cost of gems, metal and additional labor costs such as stone setting or hand engraving are added.

At Mardon, we appraise lots of fine jewelry by doing actual price comparisons and know that the quality and price of our one-of-a-kind pieces compares very favorably with jewelry from well known brands like Peter Storm, Tacori, Scott Kay, and Tiffany. And these branded pieces are usually limited editions, not one-of-a-kind!

We invite you to review the design process on our website or better yet, stop on by the shop for a free design consultation and estimate. You may be surprised how easy it is to own unique jewelry made for you alone.

If you can dream it, Mardon can create it.

Tags: CAD, CAD jewelry design, CAD/CAM, Custom Jewelry, Fabrication, one-of-a-kind, Peter Storm, Scott Kay, Tacori, Tiffany