Custom Jewelry Takes a Slow Boat to China

June 10th, 2009 by James L. Sweaney, CGA, FGA. GGYesterday morning, we delivered this beautiful emerald and diamond ring to a delighted customer. We really have to thank this couple for their patience– the entire design took almost four months to complete!

Our client, let’s call her Mrs. Green, had seen a platinum ring similar to this at a well known gallery in Santa Barbara. She asked the folks at that gallery if they would make their ring for her in yellow gold, with emeralds. To her disappointment, they declined.

Mr. Green, wanting a nice gift for his lovely wife, and not to be denied, had a jeweler in the LA jewelry mart make the ring. Long story short, the new ring wasn’t great for several reasons– the jeweler set the center emerald in a “gypsy” style flush mounting, but he set the stone from the back in a non-traditional way, with prongs that just held the stone in position below the opening in the gold. The center emerald was never tight, and since it was buried in the mounting, just didn’t show very well. The quality of the small emeralds and diamonds and the way they were set was mediocre, so the small emeralds began falling out with regularity.

The original jeweler added small prongs around the small emeralds. The extra prongs made the ring rather unsightly and Mrs. Green found the ring to be very uncomfortable to wear — and the stones still kept getting loose and falling out. Mr. Green even tried epoxy, to no avail.

They came to Mardon and asked us to fix their problem. We told them there was no practical way to fix the ring- it just wasn’t made properly to begin with. The bottom line– we decided to make a brand new ring similar to the original design, but with some much needed modifications.

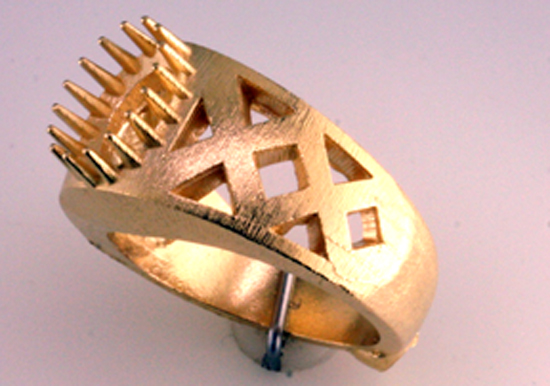

We created this design in CAD for Mr. and Mrs. Green. One of our innovations was to set the center emerald up on top of the ring so it would show to best advantage. We protected it with a gallery of small prongs– decorative and secure. Also, because her original small emeralds had been damaged by wear and many attempts to tighten them, we recommended using Chatham Created Emeralds instead– the quality of the material and the cutting is better so the stones would be more durable and secure.

CAD Images for Client

To China and Back

The ring required 2 sizes of square step cuts and 3 sizes of triangle step cuts– we made sure to order extra emeralds in case of breakage. Chatham asked us to send them our casting so they could cut the stones to fit– turns out their cutting facility is now in Hong Kong. It just so happened that the timing of our job coincided with a Chinese holiday, so the casting was at the cutting factory for almost two months! Definitely a slow boat.

Because of the delicacy of the triangle shapes and the close tolerances, our setter had to proceed very carefully. In fact, he told us this job required more setting time than any other job he had ever done.

We think the result was worth it. Even though the ring took a long time to complete, we did it the right way and solved our client’s problem. As custom jewelers, that’s really our job.

Hugs and kisses all around! Mrs. Green has the ring of her heart’s desire, and Mr. Green can relax and enjoy his wife’s pleasure. We love it!

Tags: CAD/CAM, Chatham Created Emeralds, Custom Jewelry, JewelSmith

June 10th, 2009 at 2:32 pm

Love the images! Really takes you through the process step by step!